- Synthesis

- Characterization and spectroscopy

- Catalytic Testing

- Computational Resources

- Other Infrastructure

Synthesis

Our synthesis laboratories are equipped with conventional and advanced tools for the synthesis of zeolite/zeotype materials, metal-organic frameworks and homogeneous-phase catalysts. These tools include:

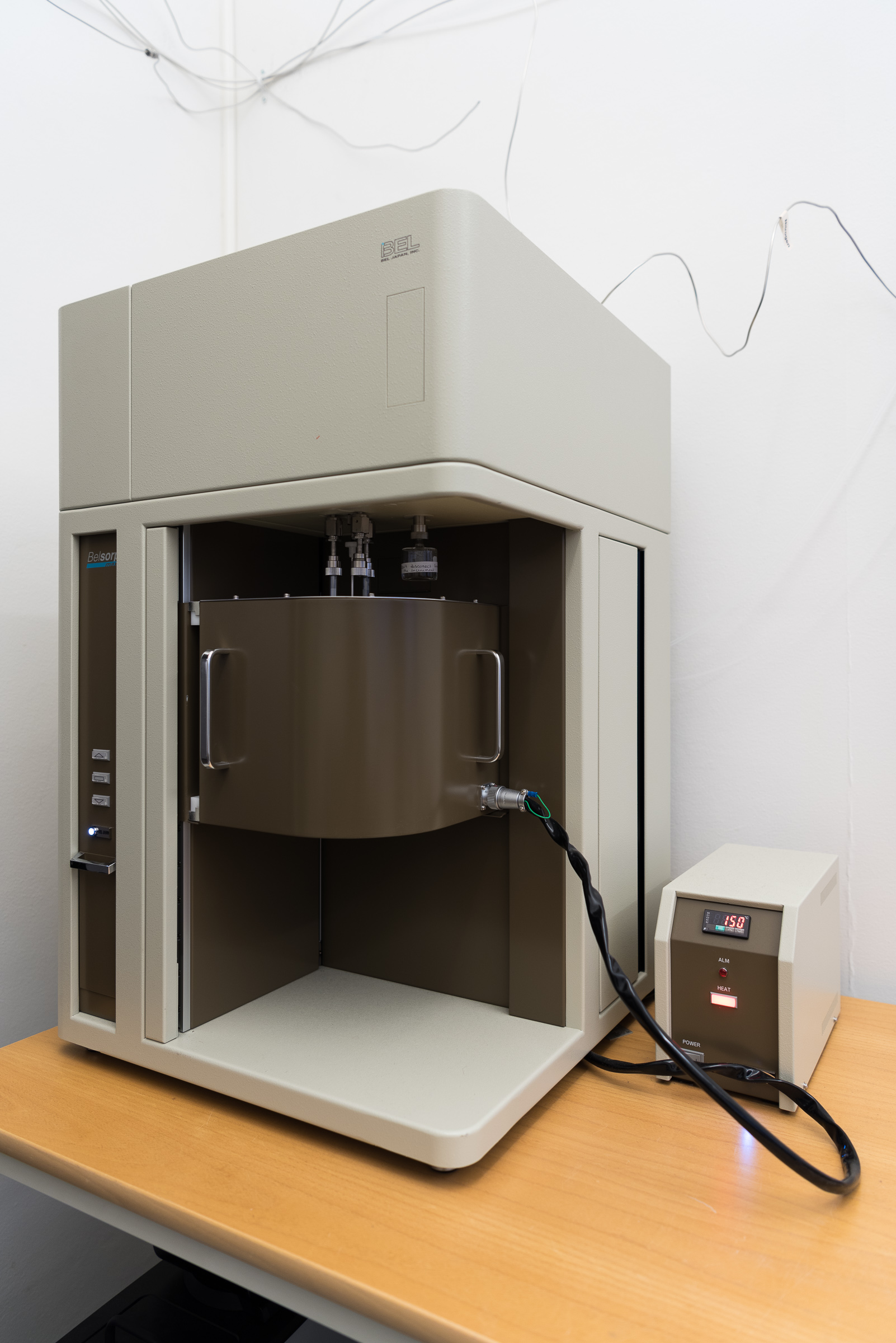

Characterization and spectroscopy

Our facilities include a variety of advanced molecular and surface characterization equipment for better understanding of the correlation between performance and properties of the synthesized materials:

Scanning Electron Microscope (SEM)

In collaboration with the Nanostructures and Functional Materials (NAFUMA) section, we also operate an advanced Hitachi SU8230 scanning electron microscope (SEM) for imaging and elemental analysis via Energy-dispersive X-ray spectroscopy (EDX, EDS).

Resource Centre for X-rays (RECX)

RECX is a national infrastructure for X-ray diffraction, scattering and imaging with lab nodes at the University in Oslo and the Norwegian University of Science and Technology in Trondheim.

Catalytic Testing

The performance of catalytic materials in processes such as methanol-to-hydrocarbons, ethylene oligomerization and CO2 hydrogenation is investigated thanks to conventional steady state catalytic test rigs. Each setup is equipped with its own computer-controlled gas-vapor feeding system, a plug-flow reactor and an on-line characterization system (gas chromatograph and/or mass spectrometer). The catalytic performances are evaluated by carrying out experiments where several parameters - reactants mixture, space velocity, temperature, pressure - are varied through time.

Temporal Analysis of Products (TAP)

In addition to steady-state reactors, the Catalysis group also operates a transient Temporal Analysis of Products (TAP) reactor.

Computational Resources

The group has access to the Norwegian national infrastructure for computational science that offers services in high performance computing and data storage. The resources are managed by UNINETT Sigma2 AS where you can check the available hardware resources and software resources.

Currently two supercomputers are utilized by our group:

- abel is the main Linux cluster at UiO.

- stallo is at the University of Tromsø and the additional information can be found here.

Other Infrastructure

In addition to these facilities, the Catalysis group has access to common infrastructures:

- Shared characterization apparatus between the University of Oslo and SINTEF in the MiNaLab building

- The MAX IV synchrotron in Lund, Sweden

- The Swiss-Norwegian Beamline (SNBL) at the ESRF synchrotron in Grenoble, France

- Other equipment available through the iCSI centre for research-based innovation.

- Other infrastructure at the Centre for Materials Science and Nanotechnology (SMN)