Scanning Tunneling Microscopy (STM) is based on a principle of quantum mechanical tunneling of electrons from the sample to the scanning tip (or reverse). During a measurement, the tip and the sample are not in mechanical contact, but are separated by a gap smaller than 1 nm. Due to the short distance there is a finite probability of electron tunneling through the gap, with the help of an applied bias. Positive bias electrons tunnel from the tip into the sample, and reverse for negative bias. For semiconductors, that will correspond to probing unoccupied and occupied states respectively. Thus measured tunneling current (I) is a function of applied bias (U) and tip-sample separation (h)

I ~ U Ae-bh

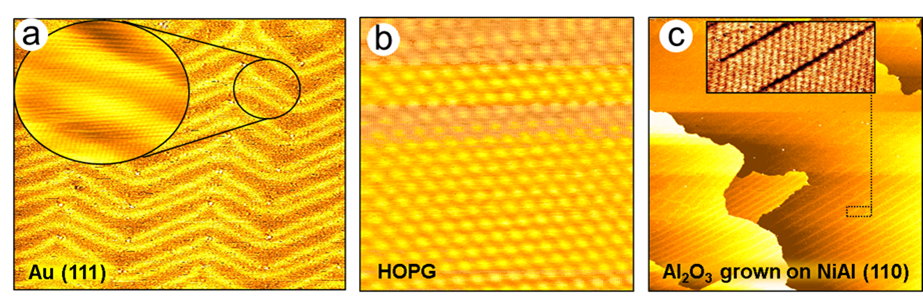

It is apparent that tunneling is exponentially dependent on tip-sample distance, and one can easily verify that a change of tip-sample distance by 1 Å, will result in a change of measured tunneling current by one order of magnitude. This is the reason for such extreme sensitivity of STM to a local electronic structure and morphology of the sample, providing information with atomic resolution. Remarkable examples of application of STM for resolving atomic morphology include Au (111), HOPG and Al2O3 grown on NiAl (110) (see figure below).

Since the invention (1981) and awarding of Noble prize (1986) to Gerd Binnig and Heinrich Rohrer, a tremendous advance in STM instrumentation has been done, allowing for multiple applications of this technique in surface science, electronics, catalysis, electrochemistry, etc.

STM can be done routinely at ambient conditions (atmospheric pressure and temperature), at the solid-liquid interface, in ultra-high vacuum and at helium temperatures, and at high pressure and high temperatures. The latter is particularly useful for operando studies (ASCAT- Operando STM) of model catalysts and can be done in a unique system ReactorSTM installed in Oslo in June 2016.